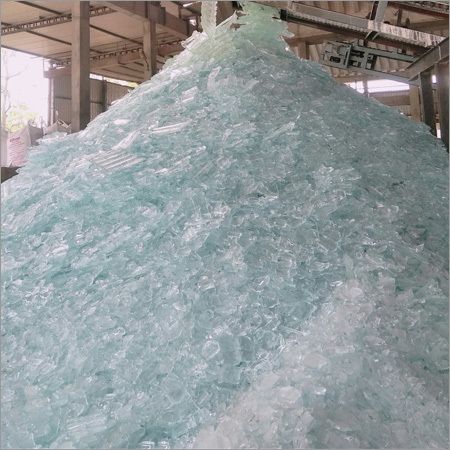

Sodium Silicate Glass

18000.0 INR/Ton

Product Details:

- Usage Soda lime silicate glass is the most widely used of all commercial glasses. Most beverage containers, glass windows, and incandescent and fluorescent lamp envelopes are made from soda lime silicate owing to its low cost, good chemical durability, and high optical transmission in the visible region.

- Purity 98%

- Molecular Weight 122.06

- Density 1.368 - 1.394

- Ph Level 10 to 13

- Properties colorless glassy or crystalline solids, or white powders

- HS Code 28391900

- Click to View more

X

Sodium Silicate Glass Price And Quantity

- 18000.0 INR/Ton

- 20 Ton

Sodium Silicate Glass Product Specifications

- 1344-09-8

- colorless glassy or crystalline solids, or white powders

- 10 to 13

- colorless glassy or crystalline solids, or white powders

- 28391900

- 1.368 - 1.394

- Soda lime silicate glass is the most widely used of all commercial glasses. Most beverage containers, glass windows, and incandescent and fluorescent lamp envelopes are made from soda lime silicate owing to its low cost, good chemical durability, and high optical transmission in the visible region.

- 98%

- 122.06

- 24 months Months

- Neutral

- Na2O7Si3

- 1,088 C

- sodium oxide (Na2O) and silicon dioxide or silica (SiO2)

- soluble in water

- Powder

- water glass

Sodium Silicate Glass Trade Information

- Cash in Advance (CID)

- 100000 Ton Per Month

- 7 Days

- Yes

- Free samples are available

- 25kg, 50kg

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

We are providing high-grade Sodium Silicate Glass. The product we offer are mainly demanded in the international market for the extraction of clean gasified fuel. It is mainly used in aluminum industries for direct combustion of aluminum. Our team of adroit professionals fabricates this product from quality components and materials obtained from the authorized vendors of the market. We examine the Sodium Silicate Glass and errors to offer our customers with perfect gasifiers.

Versatile Industrial Applications

Neutral sodium silicate glass is a cornerstone in the production of soda lime silicate glass, the most widely used glass type globally. It is commonly found in glass windows, beverage containers, and lamp envelopes. This widespread adoption is due to its affordability, durability, and outstanding chemical and optical properties, which make it indispensable across multiple industries.

Distinctive Physical and Chemical Properties

This product typically presents as a colorless glassy or crystalline solid or as a fine white powder. With a purity of 98% and a melting point of 1,088C, it ensures reliable performance in demanding environments. Its high pH range and excellent solubility in water further increase its versatility in manufacturing and industrial processes.

Reliability and Shelf Stability

Sodium Silicate Glass offers a 24-month shelf life when stored properly. Its stability as a crystalline solid or powder ensures ease of handling and consistent performance. Distributed, supplied, and traded across India, its widely accessible for manufacturers and commercial users alike.

FAQs of Sodium Silicate Glass:

Q: How is Sodium Silicate Glass typically used in industry?

A: Sodium Silicate Glass is predominantly used in the manufacturing of soda lime silicate glass, which is then employed in producing beverage bottles, windows, and lamp envelopes due to its low cost and high durability.Q: What benefits does this glass offer compared to other commercial glasses?

A: This type of glass provides excellent chemical durability, high optical transmission in the visible spectrum, and affordability, making it the preferred choice for most commercial and domestic glass products.Q: When should Sodium Silicate Glass be chosen for production?

A: It should be selected whenever there is a need for products requiring good chemical resistance, optical clarity, and cost-effectiveness, such as in bottles, flat glass, and lighting applications.Q: Where is Sodium Silicate Glass available for purchase in India?

A: Sodium Silicate Glass is distributed, supplied, and traded throughout India, making it accessible from numerous chemical suppliers and glass manufacturers.Q: What is the typical process of converting Sodium Silicate Glass into usable products?

A: The powder or crystalline form is combined with other raw materials and melted at around 1,088C to form glass that can then be shaped or molded into final products like containers or sheet glass.Q: How does the pH level of Sodium Silicate Glass impact its applications?

A: With a pH of 10 to 13, Sodium Silicate Glass is alkaline, enhancing its chemical resistance and making it suitable for applications requiring longevity and protection against environmental degradation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chemical Supplies' category

"We are accepting order above 5 tons"

Request A Quote

Request A Quote